Here you will find older used HUDDIG models that can be purchased from our dealers.

Older Models

HUDDIG 1260 D

HUDDIG 1260D was partially built using technology taken directly from our hybrid system Tigon Technology. Among other things, the response time of the new steering system in the 1260D was seven times faster than its predecessors. Year of manufacture: 2017-2020

HUDDIG 1260 C

HUDDIG 1260C is equipped with a Cummins turbocharged diesel engine QSB6.7 that meets environmental standard Stage III B. This means a powerful excavator loader with reduced emissions of nitrogen oxides and soot particles. HUDDIG 1260C is a powerful, flexible excavator loader, built to work with a high degree of precision, all day, everyday. Year of manufacture: 2012-2017.

HUDDIG 1260 B

HUDDIG 1260B came with even better traction than its predecessors, which was the result of new axles, MTL generation II, new transmission and a newly developed hydrostatic transmission. The new gear ratios meant increased traction and the HUDDIG 1260B became stronger than ever. Together with CommonRail high pressure injection, the machine achieved even better fuel economy. Year of manufacture: 2008-2012.

HUDDIG 1260

With its new, powerful Cummins QSB 6.7 stage engine, the new Huddig 1260 is in a class of its own. Stronger than ever and with 36% higher torque than before. This model also received CommonRail high pressure injection, improving fuel economy. The machine also received significantly more rounded styling. The hood is now made of GRP (glass reinforced plastic) and is in three sections. Each section is easy to open and close, which means easier servicing and access to the engine. Year of manufacture: 2006-2008.

HUDDIG 1160 D

The new D series of 1160 offered further improvements for operators. The D-series had a completely newly designed cabin with, among other things, automatic interior lighting, new sound-insulating interior material and a rear view mirror in excavator mode that made the working environment even better in the HUDDIG 1160D compared to the previous 1160 model. Year of manufacture: 2004-2006.

HUDDIG 1160

HUDDIG 1160 was developed with the operator environment in mind. The cab was updated with a new ergonomic driver's seat, digital Parker Cancontrol levers and smarter software for maximum flexibility, for example, when Excavator. The model also got a more powerful 152 hp engine, larger fuel and hydrostatic tanks, as well as remote control. Year of manufacture: 1997-2001.

HUDDIG 1060 C

Huddig 1060C - an effective and flexible excavator loader especially adapted for working where space is at a premium. The speed and power of the durable machine made it a loyal partner in, for example, an urban environment. The biggest news on this model was the powerful 103 kw (140 hp) Cummins engine. Year of manufacture: 2006–2012

HUDDIG 1060 B

One of the main changes on the Huddig 1060B compared to its predecessor is the even stronger loader, the breakout force of which has increased by an impressive 29%. Electronics were also changed and provided the opportunity for an even more economical driving style. The hydraulic system was also updated, which resulted in amazing excavator arm flexibility. Year of manufacture: 2008-2011.

HUDDIG 1060

HUDDIG 1060 took the company another step forward in the industry. New legal requirements regarding environmental class 3 engines pushed the development of engine blocks and the electronic fuel injection system. This resulted in a torque increase of 10% in HUDDIG 1060 models compared to the previous model and the machine also achieved a lower fuel consumption. Year of manufacture: 2006-2008.

HUDDIG 960 C6

Huddig 960 C6 was designed based on customers' specific requirements and wishes. The machine was first manufactured in 1984 and the result was a construction machine that combined strength, agility, efficiency and comfort. The oscillation pivot with low positioned pendulum shaft, hydrostatic operation and automatic diff brakes gave the machine unmatched traction and stability. Year of manufacture: 1989-1992.

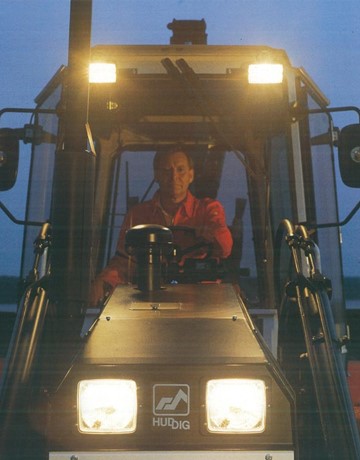

HUDDIG 960

HUDDIG 960 is a machine built for extreme terrain conditions but also for versatile use in confined spaces. Good visibility combined with articulated steering gave the driver full control of the machine. The focus was on optimizing safety and comfort when it came to excavator loaders. This resulted in a cab that, in design and function, provided perfect harmony between operator and machine. Year of manufacture: 1983-1989.

HUDDIG 860 D

When HUDDIG 860D was launched, it was the result of several years of development and testing. The D-model's newly designed cab provided significantly larger interior space and much better visibility because the driver's seat was placed 5 cm higher than previous models. Other features of this machine included a new, six-speed transmission, as well as better comfort and ergonomics. Year of manufacture: 2005-2006.

HUDDIG 860

A smaller and versatile excavator loader with the performance of the large machine. With the help of customers and dealers, this excavator loader grew up. The operator environment was designed to provide the best possible visibility, safety and convenience. A wide door, a non-slip entry, a flat floor, a deeply drawn window pane in excavator mode and opening side window contributed to the high level of comfort. Year of manufacture: 1997-2001.

HUDDIG 760 M4

HUDDIG 760 M4 was a further development of HUDDIG 760 with several smart functions. One of the big innovations was proportional valve control (PVC) – a programmable electric servo for working hydraulics that together with the newly developed minilevers provided an unbeatable working environment with unique fine-adjustment possibilities. Year of manufacture: 1990-1994.

HUDDIG 760

HUDDIG 760 was a revolution in its day. The industry had never seen such a multifunctional, versatile and easy-to-operate machine. With its oscillation pivot, automatic pendulum locking, four-wheel drive automatic diff brake and more unique features, this 7.5 ton machine set a new standard in the industry. Year of manufacture: 1986-1989.