Articles

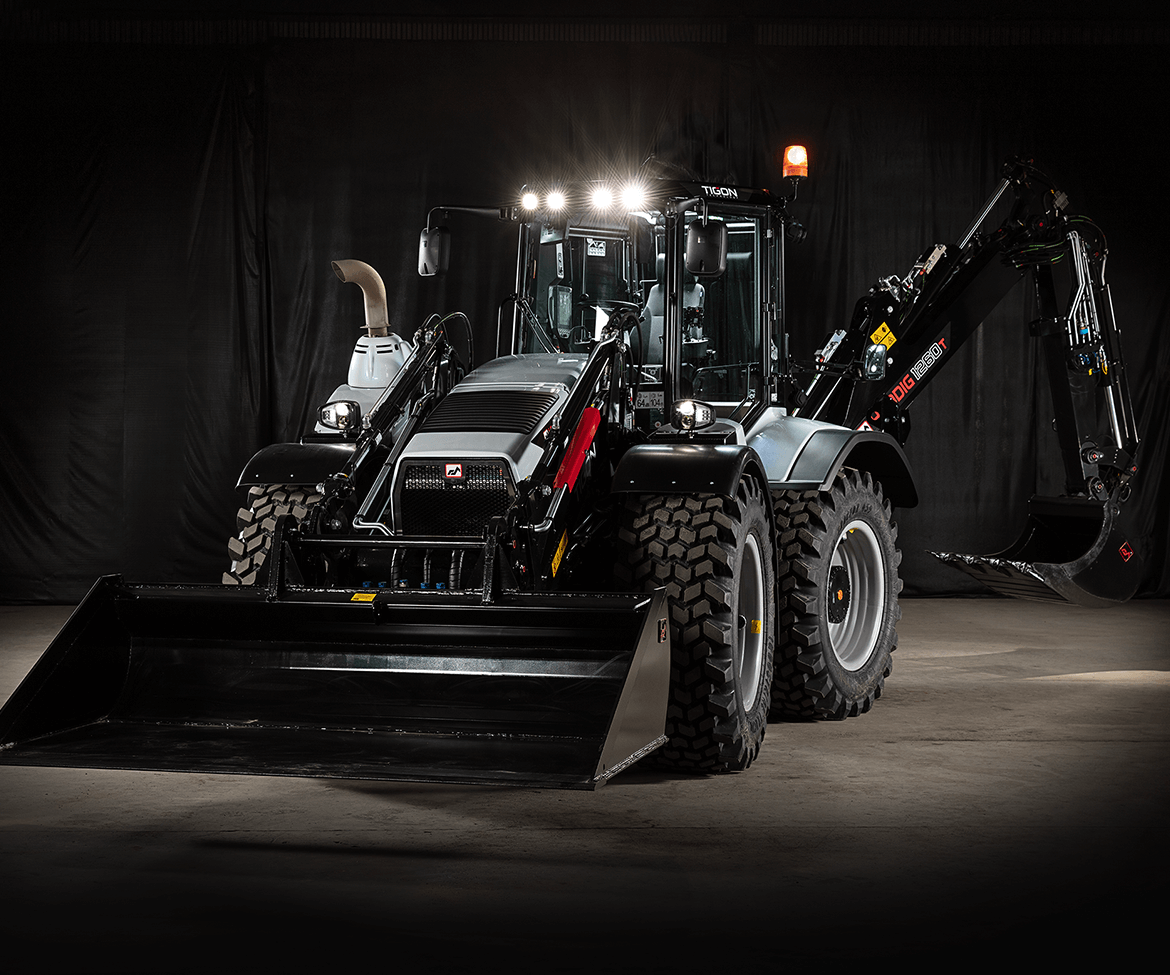

Outstanding results for HUDDIG 1260T

Ecoloop is an independent Swedish organization working to drive tomorrow's circular resource management. For 14 weeks, Ecoloop tested Huddig's hybrid machine, the HUDDIG 1260T, in real-life conditions to determine how much lower the machine's fuel consumption and emissions are, compared to traditional construction machines. The results even exceeded the expectations of Huddig's engineers.

"It has been interesting to test this hybrid machine, the first series-produced machine of its kind. Many people think that electric power means a reduction in performance and power, but here we had the opportunity to test how the machine works in the field," says Ann Segerborg-Fick at Ecoloop.

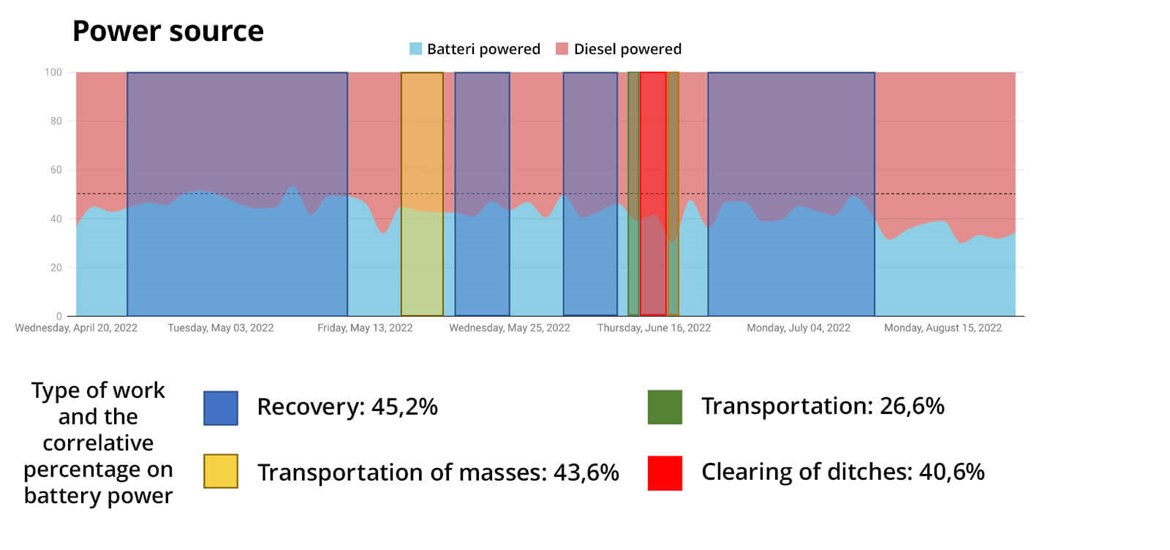

During the 14 weeks of the test, the machine performed everyday tasks in the construction industry. The studies included restoration work (filling in trenches), transporting masses, and chain clearing roadsides. The machine's primary driving setting was ECO-mode, which combines electric and diesel power for the most environmentally efficient driving possible. The tests were carried out without major technical setbacks and gave us good feedback from the drivers. So, what were the results of the tests?

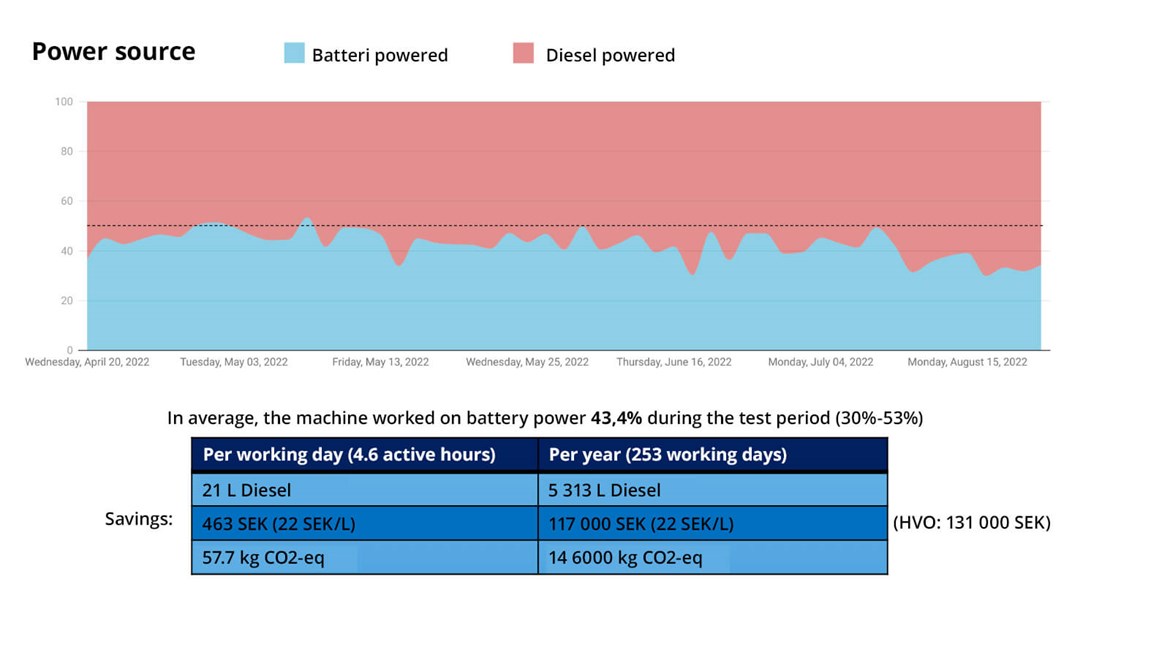

Test results - battery drive vs. diesel drive

During the test period (20 April - 19 August 2022), the machine operated for 4.6 hours/working day. These days, the machine was powered by the battery for a complete 43.4% of the time, which resulted in a fuel saving of about 21 liters of diesel/working day. This gives a cost saving of 463 SEK/working day (based on a diesel price of 22 SEK/liter) or a total of 117 000 SEK/year (based on 253 working days/year). Operation on battery drive also reduced the machine's CO2 emissions by 57.7 kg/working day or a full 14 600 kg/year.

Comment

"These figures clearly show the savings made using this hybrid machine. Suppose the industry were to replace 10% of its traditional diesel-powered machines with electric and hybrid models. In that case, we are talking about reducing CO2 emissions by thousands of tons annually. Adding the fuel cost, we see savings of millions of SEK per year," Lars Lindahl, CEO of Huddig, says.

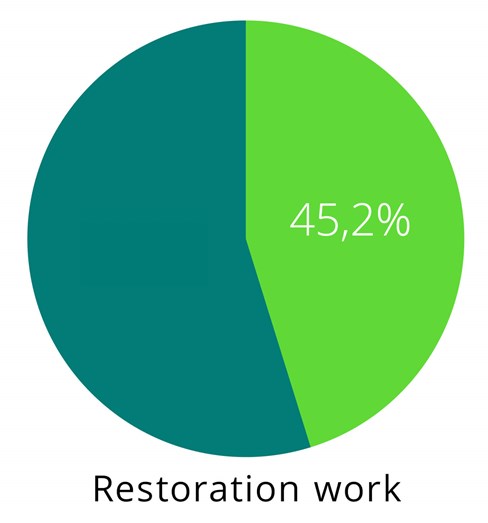

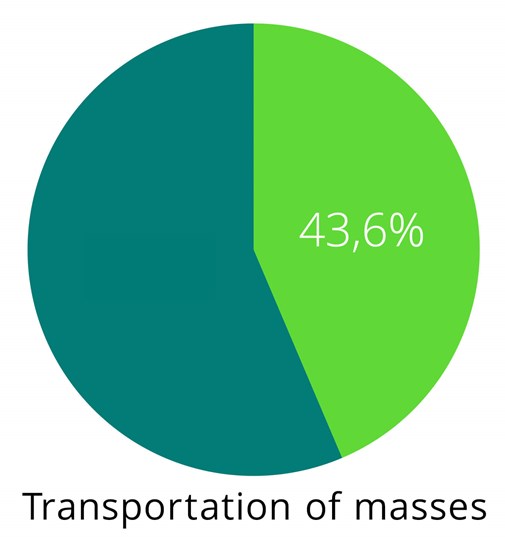

Test results - Working day on electric power

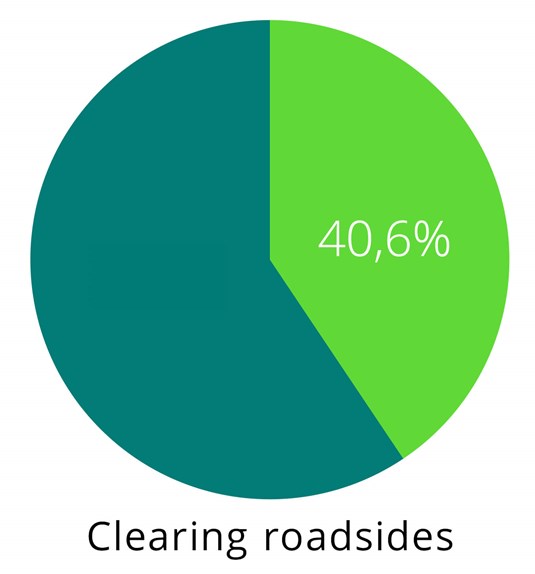

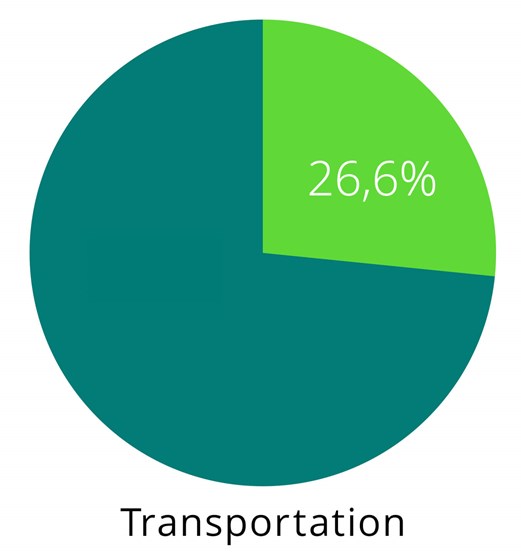

When we take a closer look at the types of tasks performed on the electric drive during a typical working day, we see the following:

Comment – working day

"Whether the machine is doing heavy work or moving between different locations, we see effective use of electric power. The ground restoration was done at over 45% on electric power, which means almost half the operating cost for this type of work. Transportation between work sites was done with 26.6% electric power. This figure is slightly lower because transport, in particular, is more energy-intensive," Ann Segerborg-Fick says.

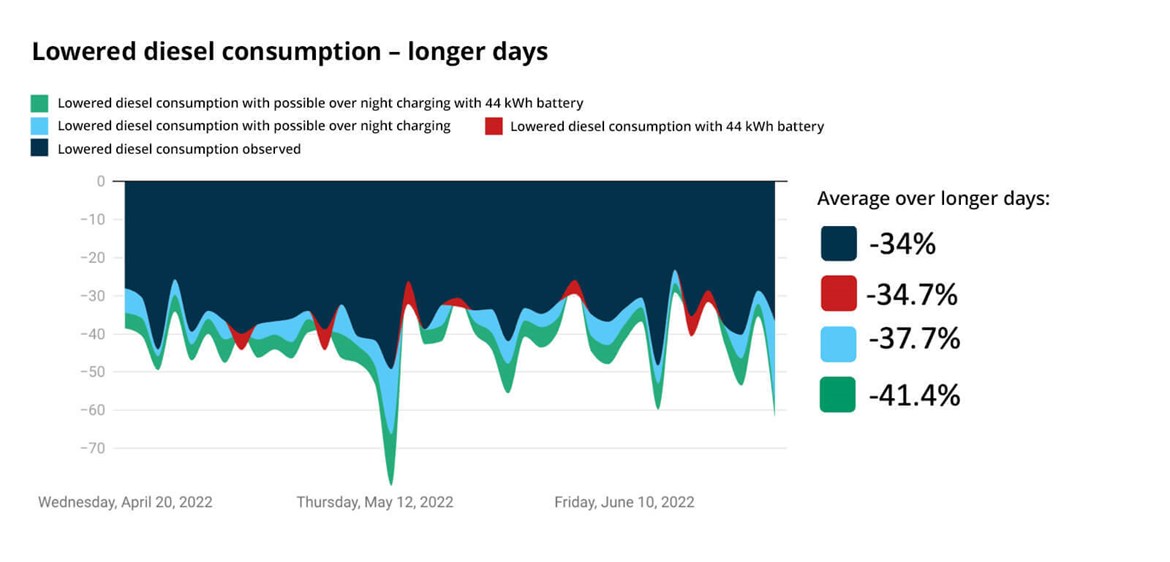

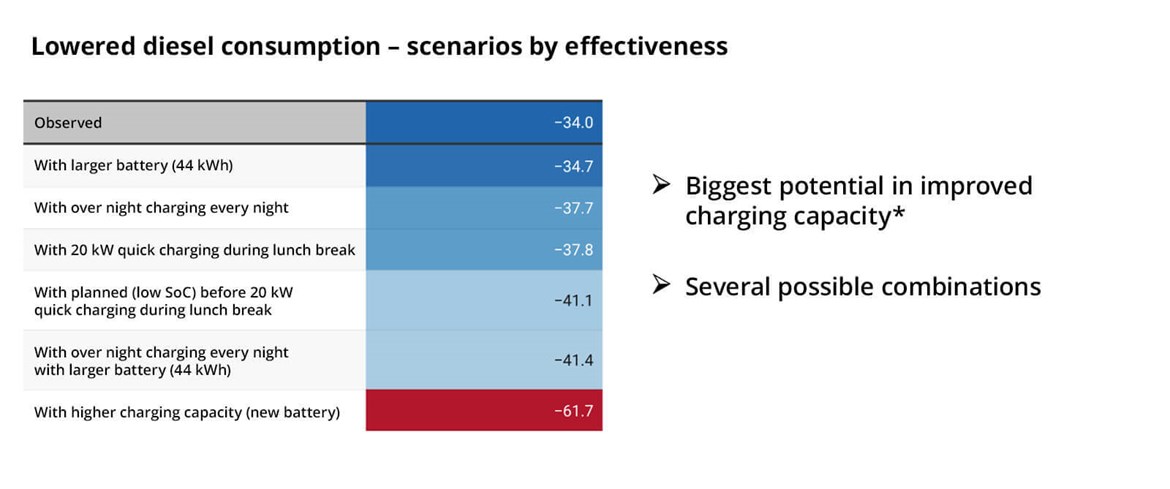

Test results – Reduced diesel consumption

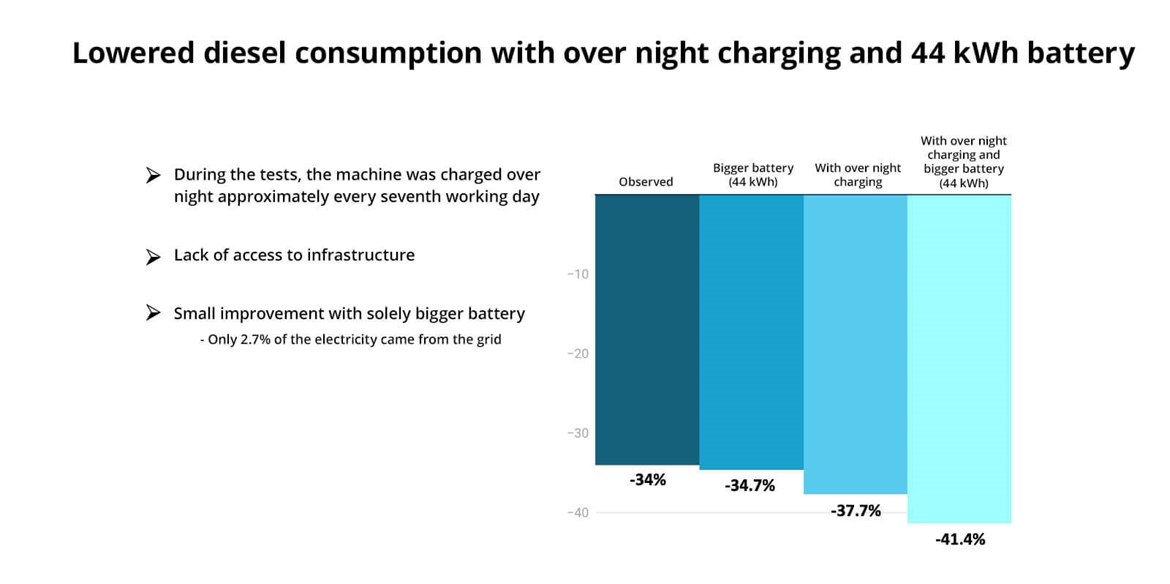

Ecoloop's tests clearly show the significant fuel savings to be made with a hybrid machine. The HUDDIG 1260T machine tested had a 33 kWh battery, but all of the new machine models (HUDDIG 1370T) come with a 44 kWh battery for even better efficiency. Charging the battery during the night provides an added benefit as the battery reaches maximum capacity. This means the actual running time on electricity is longer, leading to further fuel savings.

The graph below shows the reduction in fuel consumption under different conditions. The upper dark blue field indicates actual fuel savings during the test period. The red areas mean calculated fuel savings using a machine with a 44 kWh battery. The light blue fields show reduced fuel consumption where night charging is possible, and the green areas indicate reduced fuel consumption with night charging and operation with a machine with a 44 kWh battery.

Comment

"With a well-planned and extended charging structure at the worksites, the fuel savings could be even higher than during the tests. When a machine can be charged at night, the effective working time increases as the machine can run solely on electricity for longer. To maximize the machine's potential and fuel savings, you should also make sure that charging posts are available," Daniel Åkerström, engineer and project manager at Huddig, says.

Other test results - Reduced diesel consumption 44 kWh battery and night charging

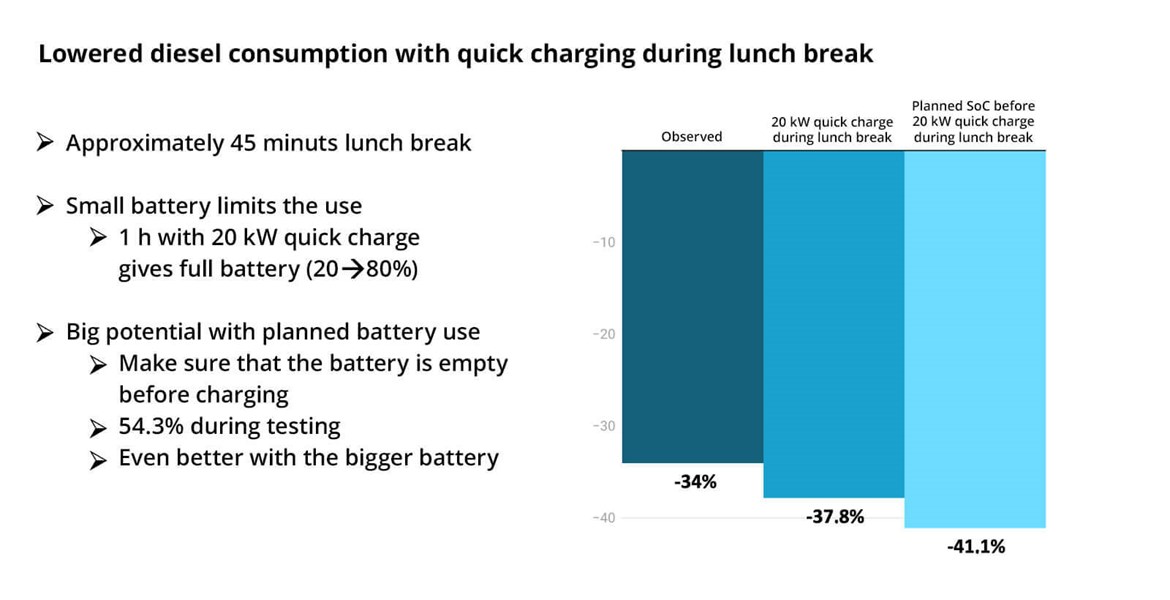

Other test results - Reduced diesel consumption with fast charging over lunch

Other test results - Reduced diesel consumption with larger charging capacity

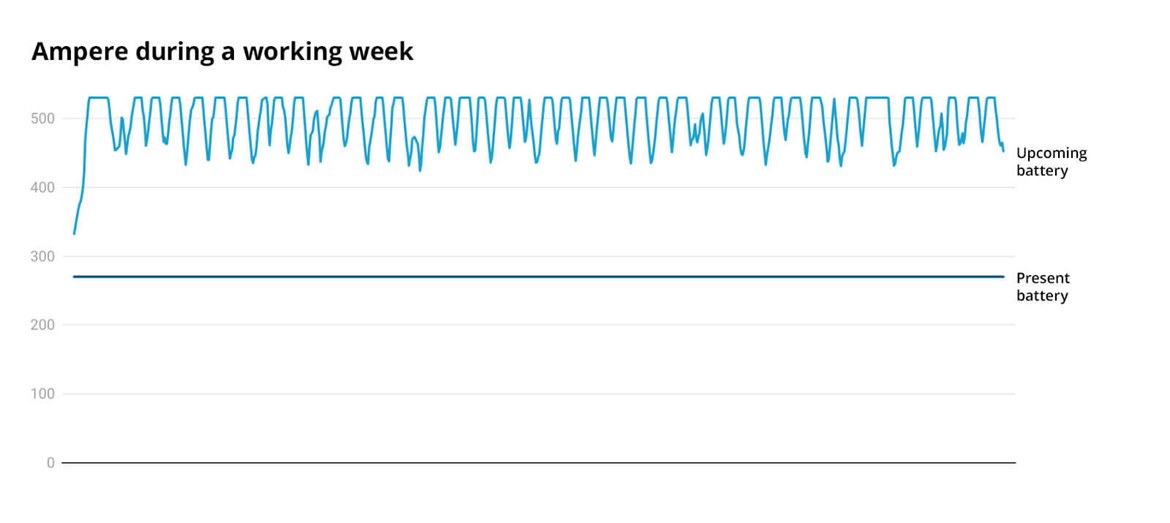

Other test results - Amps during one week of operation

Other test results - Scenarios based on efficiency

Test results - Charging structure

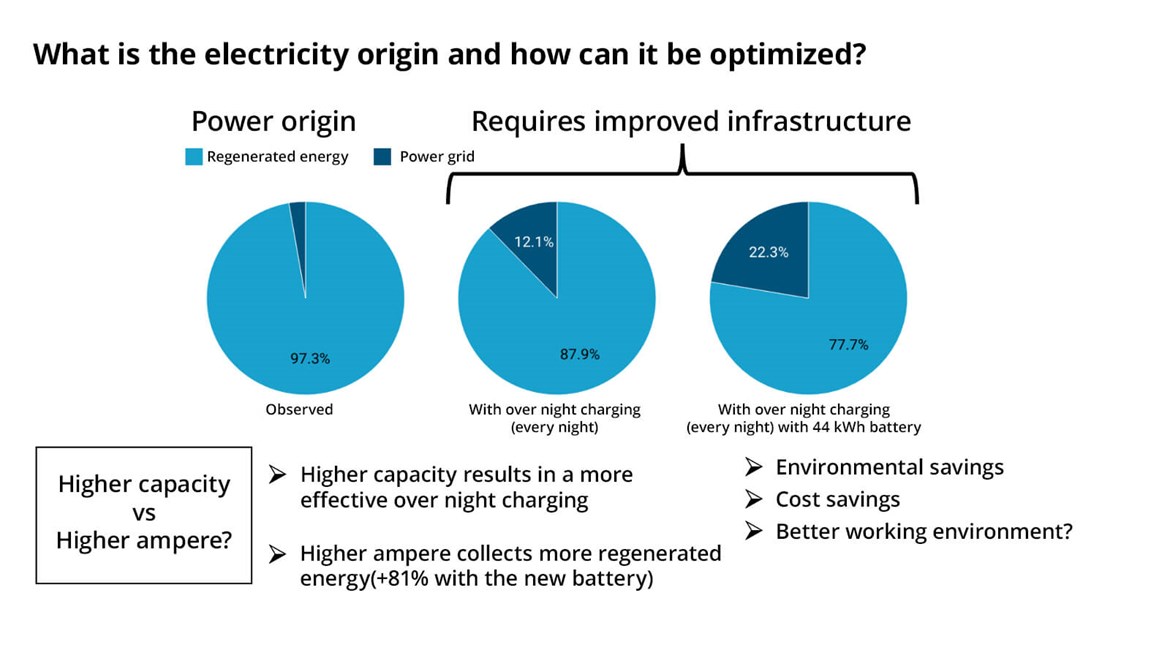

Ecoloop's tests also show where the electricity that powers the machine is generated and how it can be optimized for the best results. In the test machine, most of the electricity was caused by regeneration from the engine, i.e., the battery recharged during periods when the machine ran on diesel. The recharge is done by so-called "waste energy" from the diesel engine and can then return the machine to pure electric operation. The graphs below show the test results and calculations where night charging of 44 kWh batteries is possible.

Comment

"Battery technology is constantly advancing, and the new models with 44 kWh batteries demonstrate the benefits of the latest technology. The higher charging current captures up to 81% of the waste energy from the diesel engine and provides a more favorable night charge due to the higher energy content", says Daniel Åkerström.

The excellent test results have also surprised Huddig's engineers.

"We saw early on in our calculations that the technology would enable significant savings, but to now see the results from a working machine in a daily environment that even exceeds our expectations - that is very exciting," continues Daniel Åkerström.

"Now, we will be even more efficient with the larger battery and later with the developed charging structure. We look forward to large and small contractors seeing the benefits of multifunctional and flexible hybrid machines in their workplaces," Daniel concludes.

Read more about Tigon Technology, the technology used in our HUDDIG 1260T and HUDDIG 1370T hybrid machines.

Graphs and charts from the report by Ecoloop.